No leaks, corrosion, tears, or production stop in the port of Antwerp-Bruges

Teblick recently had the opportunity to work on an interesting project in the port of Antwerp-Bruges. Here, two Belgian highly specialized companies join forces to recycle waste and residual flows from the industrial maritime sector: Waterleau is internationally renowned for their expertise in water treatment. MAC2 recycles oil-containing waste from the maritime and industrial sector so that it can be used as a new raw material. Their team effort contributes to the well-being of our environment. No wonder our engineers were immediately excited when we at Teblick got the chance to work on this major project!

THE CHALLENGE

These companies take on the responsibility of cleaning the tanks of ships and trucks that transport liquids to the port of Antwerp-Bruges. As soon as the ships have unloaded their cargo they dock at the port’s dry docks, where our clients get to work.

When their engineers determined that the piping was outdated, they decided now was the time to update the site. During the cleaning processes of the tanks, certain gases are released that must be handled with great care. That is why they gladly entrusted this task to us.

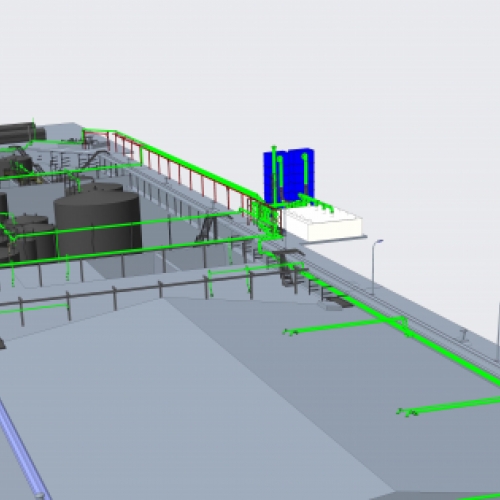

Our company was commissioned to both design and build the extraction systems for the tanks. As a result, the workspace was upgraded to an ATEX zone 1. The system we created had to be able to safely collect, transport and clean residual gases from the suction tanks – without damaging the environment.

OUR SOLUTION

Our team came up with a possible solution to the problem at hand, suggesting a construction in PPs-EL. This plastic only entered the market commercially a few years ago and is not yet fully established in the industry. At Teblick we have been working with it for quite some time. Therefore, we were able to rely on our accumulated knowledge of the technical feasibility and optimal layout of this construction for our customer.

Although many companies have not yet heard of PPs-EL, our customer was immediately convinced about the benefits associated with this material. This polypropylene variant not only has a self-extinguishing property, which prevents fire from spreading through the piping, but is also electrically conductive. As a result, this plastic can be used by our customer in explosion-sensitive zones. This material is a good alternative to traditional types of steel, such as stainless steel 304 and 316, galvanized steel or C5 marine coating. Not only are these metal counterparts chemically non-resistant, they also need to be replaced every few years due to wear and tear.

Having finalized the drawings, we began to manufacture the most difficult collectors and pipe spools. Then we started with the assembly and connection of the construction on site.

A SMOOTH TRANSITION

Time is money, especially in the port of Antwerp-Bruges. That is why we worked out a solution without production stop for our customer. By ensuring that no tank was out of service for more than two consecutive days, our customer's business was not compromised. Our team built this new system parallel to the aging pipes to ensure a smooth transition from the old to the new pipes. After the new pipework was installed, the old pipes were removed.

SOME NUMBERS

- 8 extraction systems, 1 biofilter and 2 containers with activated carbon were commissioned

- To date, >3.000 hours worked on-site

- 1175 meters of piping; network designed at Teblick and assembled on-site

- 2 PPs-EL pipe diameters were specially produced by our supplier for this project

Numbers and constructions to be proud of, custom plastic installations perfect for our client!