Scrubbers

What is this?

A scrubber is an air-cleaning device that extracts toxic and/or corrosive components from a gas flow. These components are absorbed in a liquid and either discarded or if possible immediately transformed into biodegradable or recyclable products.

Why use scrubbers?

A safe and highly efficient way to clean your gas flows

One of our specialities is eliminating ethylene oxide and/or propylene oxide from vent flows of reactors or EO sterilizers. The pollutants are absorbed and converted into ethylene glycols and/or propylene glycols. Inherently, this transformation into glycols is a very slow reaction. However, thanks to our chemical and technical know-how we can create scrubbers that are compact yet ensure continuous operation. No time to waste!

Low operational costs

Compared to using activated carbon filters or an incinerator, scrubbers use little energy and require much less maintenance. Choosing automated absorption fluid renewal brings down operational costs even more.

Environmentally friendly option

The scrubber liquids that eliminate the pollutants (compositions depend on use) are internally circulated until they need to be renewed, which means water consumption is as low as possible.

Additionally, production waste does not have to be burned. Instead, the biodegradable output could be sold as raw materials to other businesses.

The Teblick-Trevi partnership

For over 30 years, Teblick has had a dedicated partner for scrubbers. Trevi Environmental is committed to engineering the optimal process, Teblick handles the mechanical engineering and construction.

Our options

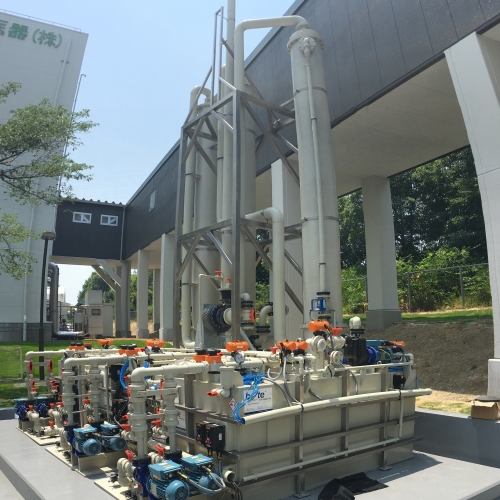

We mostly engineer and manufacture 3 types of scrubbers. Which type or combination of types best suits your needs depends on the size of, and expected fluctuations in gas flow, as well as the type of contamination that needs to be eliminated. In short:

- Packed Tower scrubber

This most common type of scrubber can easily handle fluctuations in gas flow and concentration. Depending on the treated gas, the concentration of pollution and required efficiency, either randomized or structured packing can be used. For process optimization (highest efficiency) we recommend using structured packing in combination with our internally developed liquid distributor. - Ejector scrubber

Self-extracting, by means of ejectors. This type of scrubber has high removal efficiency and is used for high concentrations of poisonous and hazardous gasses. The flow of treated air is rather low. - Jet Venturi scrubber

Self-extracting, to be used for gas flows contaminated with dust and particles, as well as gas cooling. In combination with a packed tower scrubber, the Jet Venturi replaces the fan.

Teblick can be your ideal partner for a fully integrated treatment installation. In addition to scrubbers, we can provide tailored solutions for the production, storage, and dosing of all chemicals needed for optimal removal efficiency. Of course, we can also supply and install the required piping to transport the gas from its point of initial emission to our gas scrubber and ultimately the treated gas can be transported to its final emission point.