The problem

One of our clients in the Port of Antwerp works with gaseous chemicals. When loading and unloading these gases the stench would be overwhelming. Initially, this was considered to be merely inconvenient, but as the company decided to expand this business activity this nuisance had to be addressed.

The solution

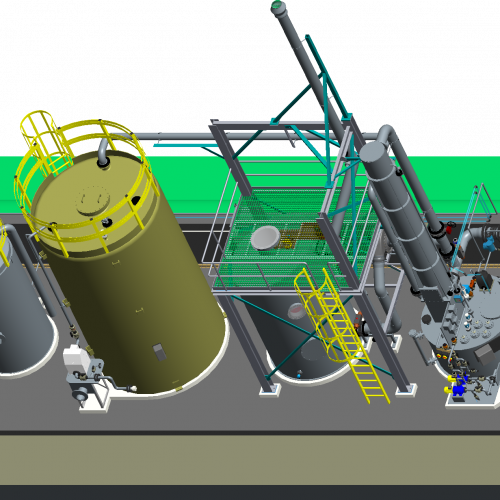

Based on the process specifications of our partner we designed, built and installed a complete packed tower scrubber for this client.

While using activated carbon filters alone would have fulfilled the efficiency requirements, the maintenance costs of such a setup was quite high.

Combining a scrubber with a downstream activated carbon filter drastically lowered the maintenance costs and added the extra benefit of an even higher efficiency.

Challenges concering this project

Neutralising the substance that caused the problematic odour required various chemicals. We built the required storage tanks, selected the right pumps and instrumentation for this project and topped it all off with a custom-made chemical distribution unit. The metal platform ensures easy access for taking measurements and swapping activated carbon. Combining all of these, we provided a complete solution for our client.

The installation was placed in an ATEX zone, so the entire installation was built in electrically conductive material.

After the factory acceptance test (FAT) in our workshop in Wilrijk, we could not simply demount the installation and transport it to its final destination. As the new installation needed to be fitted between existing structures on an already rather full company site, there was limited space for storage and manoeuvring. Therefore we sent one truck every day with the materials to build the next part of the installation, keeping in mind our client’s requests to not leave anything overnight and to keep all roads open.